Once initiated the growth rate of the pit can be relatively rapid resulting in deep cavities and even through-wall attack.

Localized corrosion such as pitting and crevice corrosion of stainless steels generally occurs in the presence of halide ions, typically chloride (e.g. coastal and deicing chloride salts – sodium, calcium or magnesium chlorides; hydrochloric acid; bleach – sodium or calcium hypochlorite; and other chloride compounds).

Pitting occurs when there is a localized breakdown of the stainless steel’s protective passive layer on an openly exposed surface. Once initiated the growth rate of the pit can be relatively rapid resulting in deep cavities and even through-wall attack. Other metals, such as aluminum, can also exhibit pitting corrosion.

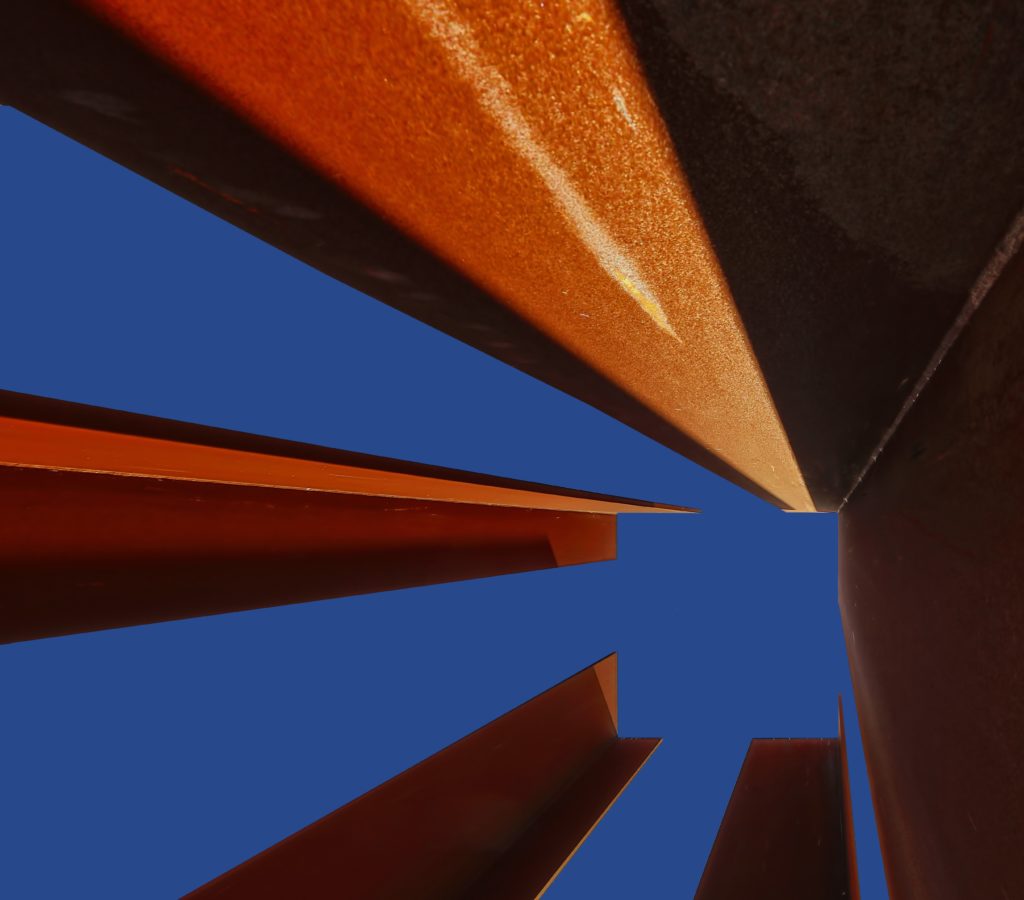

Crevice corrosion occurs at locations where oxygen cannot freely circulate such as tight joints, under fastener heads and in other circumstances where the pieces of metal are in close contact.

Chloride salts, pollutants and moisture from the environment accumulate in the crevice. The environment inside the crevice becomes depleted of oxygen, enriched in chlorides, and acidified which promotes the breakdown of the passive film and anodic dissolution.

The important environmental factors that favor localized attack are higher chloride content, higher temperatures, lower pH, and more noble corrosion potentials.

Because of this limitation, one must be careful when using the PRE number to make material decisions.

The resistance of a stainless steel to localized attack is strongly related to its alloy content. The primary elements that contribute to the pitting and crevice corrosion resistance of austenitic and duplex stainless steels are chromium (Cr), molybdenum (Mo), tungsten (W), and nitrogen (N). Tungsten, although not commonly used, is about half as effective on a weight percent basis as molybdenum in improving corrosion resistance.

The Pitting Resistance Equivalent number or (PREn) has been developed to correlate a stainless steel’s composition to its relative pitting corrosion resistance. The PRE relationship for austenitic and duplex stainless steels is usually given as follows.

PRE = %Cr + 3.3%(Mo + 0.5W) + x%N

where x is typically given as either 16 or 30

Although this relationship has been developed to rank pitting resistance, it also provides a relative ranking of a stainless steel’s crevice corrosion resistance.

The PRE number is related to the grade’s resistance under ideal conditions and does not address factors such as the presence of intermetallic phases, improper heat treatments, or inferior surface condition. Because of this limitation, one must be careful when using the PRE number to make material decisions.

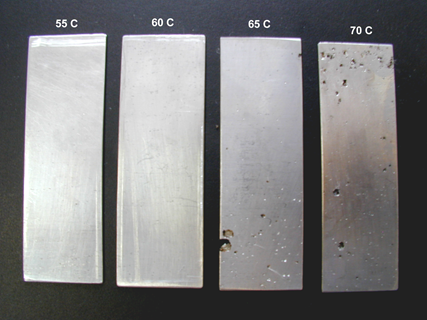

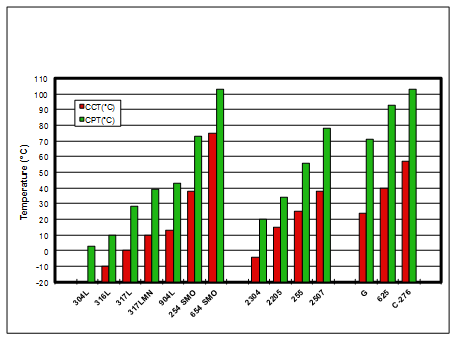

The relative resistance to localized corrosion for different alloys can be quantified by determining the critical temperature required for initiating attack. The critical pitting temperature (CPT) or critical crevice corrosion temperature (CCCT) is measured using either immersion test methods, such as those outlined in ASTM G48, or by electrochemical methods, such as the ASTM G150 test method. When a higher critical temperature is necessary to initiate attack of a stainless steel alloy, it is more resistant to localized chloride attack. These critical temperatures relate to standard laboratory environments and are not readily transferable to practical operating environments but they provide an indication of relative performance.

As is shown in Figure 4, the CCCT of any alloy is lower then the CPT. Figures 2 and 3 also illustrate that crevice corrosion can occur when the remaining fully exposed surface of the stainless steel is not exhibiting pitting corrosion. This makes designing to avoid or seal crevices an important factor in achieving the desired level of performance.

Figure 4: CPT and CCCT for various austenitic stainless steels, duplex stainless steel, and nickel alloys measured in 6% ferric chloride

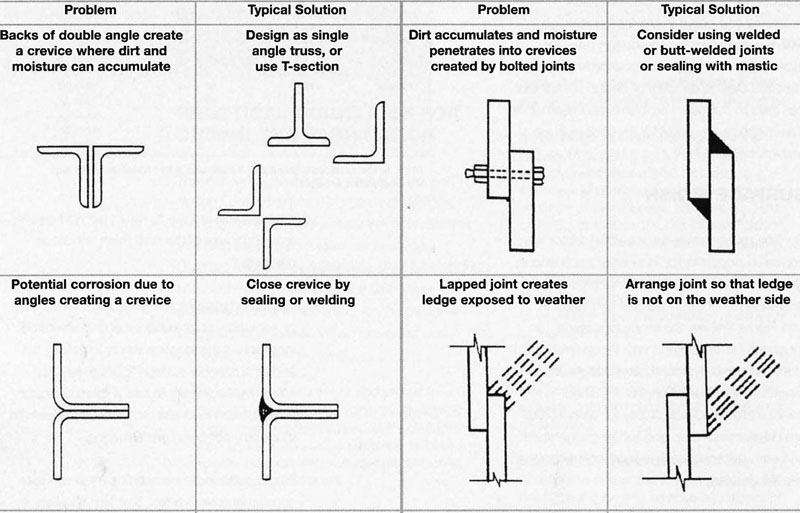

Sealing or eliminating tight joints during design can often avoid crevice corrosion.

Pitting and crevice corrosion can be avoided by either choosing a more corrosion resistant stainless steel or by changing the service environment so that it is less aggressive. For example, lower service temperatures or reduced levels of chloride can substantially reduce the aggressiveness of the environment.

Sealing or eliminating tight joints during design can often avoid crevice corrosion. In immersed applications or where standing water will be present, welding is the preferred solution. In true water shedding applications, like roofs and wall panels, flexible inert washers or construction sealants can often be used effectively but they should not be considered for water pooling or immersion. Figure 5 illustrates common tight crevice conditions and possible solutions.

All metals can exhibit crevice corrosion but the service environment conditions under which it can occur and the location where metal loss occurs varies (e.g. inside or just outside the crevice) with the metal family. When two different metals create a tight crevice, both crevice and galvanic corrosion can potentially occur.